Most mainstream cars fall in that range; vehicles with complex or active anti-roll systems—think Toyota KDSS, BMW ARS and some Land Rover/Mercedes setups—or cars that require dropping the subframe to access bushings can run higher, occasionally over $1,000 due to extra labor and specialized parts, which pushes up anti-roll bar repair cost.

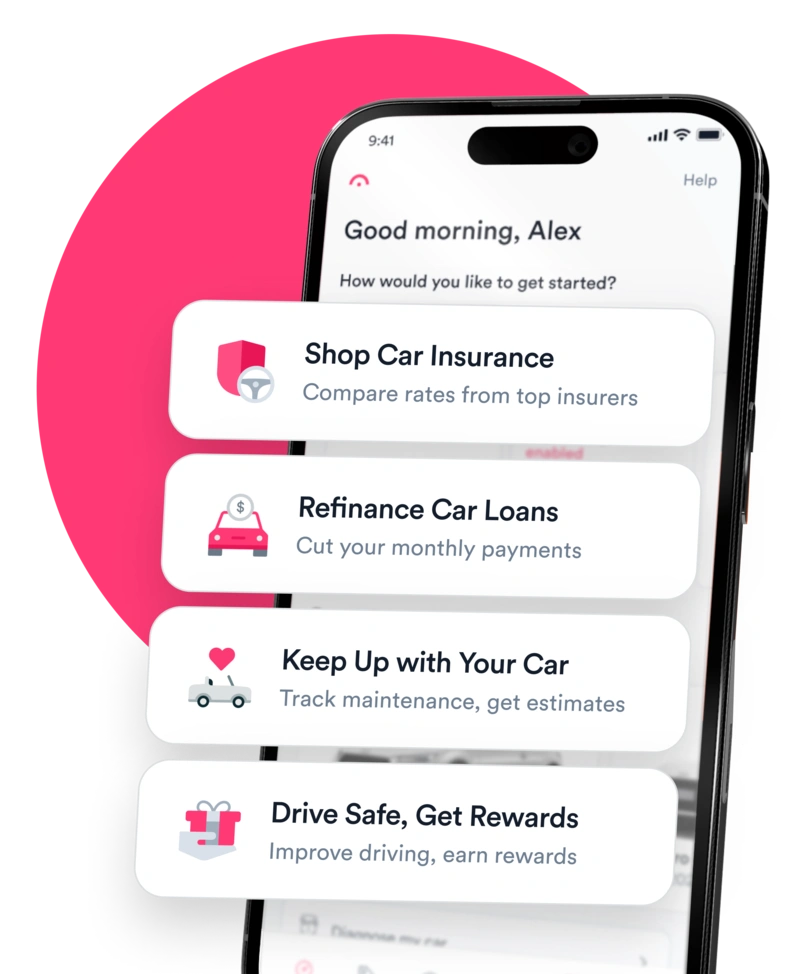

Join other customers who’ve compared costs for their exact vehicle and location and found the right shop with the Jerry app.

Real customers Jerry helped

While pricing can vary based on unique factors – like exact vehicle, location, and parts – Jerry uses real customer experiences to show what drivers are paying right now. Here are a few examples:

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

What is a sway bar?

A stabilizer bar connects the left and right wheels of your suspension to reduce body roll when you corner. Without a functioning sway bar, sharp turns make the car lean more, which hurts stability. Over time, bushings dry out and links wear down, turning that solid feel into rattles, clunks and sloppy handling. The bar itself rarely fails on normal cars; links and bushings are the usual culprits. Catching this early reduces suspension wear and keeps you safer on the road. If you’re unsure whether the sway bar is the culprit, describe the noise or handling feel to Jerry’s artificial intelligence (AI) chatbot for a quick, guidance-level check.

Symptoms of a failing sway bar

Here are a few common symptoms of a failing sway bar that Jerry customers are keeping in mind:

- Clattering noises from the front end of the car when going over bumps.

- Clicking sounds when making turns.

- Poor handling.

Cost breakdown: why the price varies

The sway bar itself is a simple piece of metal, but Jerry customers are seeing the cost of repairing or replacing it change a lot depending on what’s worn out and what kind of car you drive. Here’s why the numbers swing so widely.

Sway bar links:

These small arms connect the bar to your suspension. Replacing the links is the cheapest repair—sway bar link replacement cost is usually $75 to $200 for parts and labor on typical cars. Many mechanics recommend doing them in pairs (both sides), which may bring the bill to between $200 and $300. Book time—sway bar replacement labor time—often runs about 0.7 to 1.5 hours total if hardware comes off cleanly; expect more in rust-prone regions where seized studs may need to be cut.

Bushings:

Rubber or polyurethane bushings keep the bar snugly mounted. Worn bushings can cause clunks or rattles. A set of bushings plus labor—sway bar bushing replacement cost—typically runs $100 to $250 on cars where access is easy. Expect 2 to 4 or more labor hours in more complex cases.

Entire sway bar replacement:

If the bar itself is bent or cracked (less common), sway bar replacement cost—also called stabilizer bar replacement cost—is $300 to $650, with labor making up about half the cost in straightforward jobs. Heavy-duty truck/SUV bars or bars integrated with active systems can cost more due to part price and setup procedures.

Vehicle type:

Luxury brands tend to run at the high end, while common sedans land on the lower side. SUVs and trucks often have larger, pricier sway bars too. Vehicles with active or hydraulic anti-roll systems can escalate into four-figure repairs because the components and procedures differ from standard passive bars.

Labor costs:

Most shops quote one to two hours for a simple links/bushings job with good access. Nationally, shop rates commonly range from about $110 to $220 per hour depending on region and shop type, so labor alone can swing the total by a couple hundred dollars. Salt-belt corrosion can also affect sway bar replacement labor time.

Your action plan: how to save money

Nobody wants to spend more than needed on a repair. Here’s how to keep the bill in check.

Get a second opinion.

Some shops push for full bar replacements when only bushings or links need replacing. Ask the mechanic to show play in the end link or a cracked bushing so you can see the problem.

Do both sides at once.

Replacing sway bar links in pairs avoids paying for another labor charge later when the other side fails.

Shop around.

Labor rates vary widely. If you’re searching for “sway bar repair near me,” Jerry’s repair estimator and mechanic finder can show shops in your area with fair pricing.

Aftermarket parts are okay.

Unless you’re driving a high-performance or active anti-roll system, quality aftermarket sway bar links and bushings work as well as OEM and usually cost less.

Combine repairs.

If you need other suspension work like shocks or control arms, bundle it in one visit to save on labor overlap.

DIY vs. pro: can you do this yourself?

For a handy DIYer, replacing sway bar links or bushings isn’t the hardest job, but it requires the right tools and safe jack stands. Jerry’s insights into parts and labor rates can help make the decision clearer. Here is a quick comparison.

Related repairs

A failing sway bar often doesn’t come alone. Here are other repairs that Jerry customers are seeing recommended together.

- Control arm bushings. If you hear clunks over bumps or feel shimmy under braking, the mechanic may check these too. Replacements usually cost $300 to $750.

- Ball joints. Worn joints can mimic sway bar noise with vertical play. They run about $200 to $400 each.

- Struts or shocks. If your ride feels bouncy, this might be the root cause. Expect $400 to $900 for a pair.

If multiple suspension parts are worn, fix them together—alignment, ride quality and tire wear all depend on it.

What our customers are asking

-

Can you drive with a broken sway bar?

-

What are the symptoms of a bad sway bar?

-

Do sway bars wear out often?

-

Do you need an alignment after a sway bar repair?

Spencer Clayton is a mechanic, writer and fabricator who has hands that know their way around engines and a passion for storytelling. He’s diagnosed complex faults, built high performance engines and custom fabricated everything from fine detail parts to entire chassis while sharing how things work and why they matter. His background in everything from dealership technician work to building high performance cars spans a large breadth of experience, and he is driven by a love of all things automotive and a desire to share knowledge.

Steve Kaleff began working on cars at the very young age of nine years old, when his dad actually let him make fixes on the family car. Fast forward to the beginning of a professional career working at independent repair shops and then transitioning to new car dealerships. His experience was with Mercedes-Benz, where Steve was a technician for ten years, four of those years solving problems that no one could or wanted to fix. He moved up to shop foreman and then service manager for 15 years. There have been tremendous changes in automotive technology since Steve started his professional career, so here’s looking forward to an electric future!

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.