Prices can vary so much because the part itself can be cheap for a common car and very expensive for certain makes, models, or luxury vehicles, and some shops use pricier brand-name parts. On top of that, labor rates, how hard it is to access the compressor, and add-ons like refrigerant, dryer, and shop fees all change the final bill.

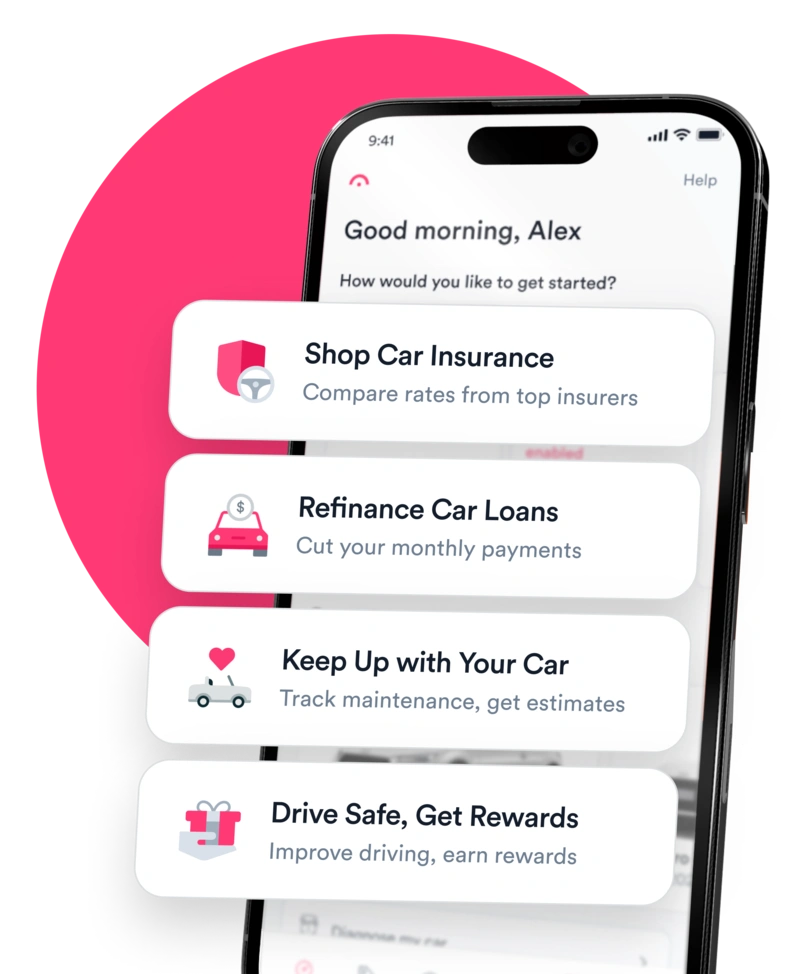

Jerry customers use the app to check local pricing for A/C compressor repairs for their exact vehicle and location, so they can get back on the road with confidence.

Real customers Jerry helped

See what an A/C compressor replacement cost could look like for drivers like you. Here are some examples of costs for real cars and locations.

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

Cost breakdown: Why the price varies

The price range for an A/C compressor replacement isn’t one-size-fits-all—it depends on your specific car, where you live, and which parts go in. Jerry shows you what other drivers are paying right now; here are some real customers we’ve helped find accurate quotes on A/C compressor replacements.

Vehicle make/model and engine layout:

Often a $300 to $1,200 range due to factors such as part availability, engine-bay access and labor time. European, luxury, hybrid and some turbo models are pricier.

New vs. remanufactured compressor:

Remans can save $100 to $400 vs. new OEM. Stick to reputable brands with solid warranties; some vehicles lack remanufactured options.

Labor time and shop rate:

Typically 2.5 to 6.0 hours. At $110 to $200/hr, that’s $275 to $1,200 in labor alone. Tight engine bays and complex accessory drives add time.

Refrigerant type:

R-1234yf (common on 2017+ models) is significantly more expensive than R-134a—often $150 to $300 more per recharge, so know your situation in advance.

Required supporting parts:

Accumulator/drier ($50 to $180), expansion valve/orifice tube ($25 to $150), and O-rings ($10 to $40). Expect $100 to $370 in parts before refrigerant and supplies.

System contamination:

If the old compressor shed metal, the system must be flushed. However, many parallel-flow condensers can’t be effectively flushed and must be replaced ($150 to $600).

What is an A/C compressor?

Your A/C compressor is basically the “heart” of your car’s air conditioning system. It’s a belt-driven pump that squeezes and moves the refrigerant through the A/C system so the air coming into the cabin can be cooled. When the compressor wears out or fails, the system can’t build pressure properly—so you’ll usually get weak or warm air instead of cold air from the vents.

If your A/C stops blowing cold air and you go to the shop, the technician might find a bad compressor, replace it and the related parts, and everything may work perfectly, but only for a few days. If you have to go back because the A/C quits again, the shop might find that the condenser is now leaking refrigerant and needs to be replaced. In that case, the compressor was just the first weak link in the chain, and once it was fixed and the system was back to full pressure, the next weak link (the condenser) failed.

This doesn’t happen with every A/C repair, but it does happen sometimes. That’s why it’s important to stay in touch with your technician and work together to get to the real root of the issue.

What are signs that you need the A/C compressor replaced?

Don’t ignore the signs of a failing A/C compressor. Here’s what Jerry has learned you’re most likely to notice, after helping drivers diagnose their cars:

- No cold air even with proper refrigerant level.

- Metallic grinding, rattling, or shrieking from the engine bay.

- Clutch not engaging or short cycling.

- Weak cooling at idle but better at speed.

- Visible refrigerant/oil leaks around the compressor.

- Black debris or metallic glitter in the system.

- Belt slippage or burning smell from a locked compressor.

Your action plan: how to save money

Smart moves can shave hundreds while protecting your new compressor. Here’s what you can do:

Do a quick driveway check.

A/C on MAX, recirc ON, fan high and hood up. Watch the compressor: pulley spins always, center hub should engage. Check fuses/relays, condenser fan, and line temps.

Get a full diagnosis first.

Relays, belts, or sensors can mimic compressor failure. A $100–$200 diagnosis beats replacing a good compressor. Jerry customers use the app to help them diagnose common signs and give them confidence before heading to the shop.

Ask for contamination proof.

Photos of orifice tube/expansion valve debris tell the story—glitter or sludge means more parts must be replaced.

Compare new vs. reman.

A reputable remanufactured with 12–24 months of coverage can save $100–$400.

Verify the quote includes everything.

Refrigerant type/weight, oil type/amount, drier/expansion device, leak testing, and photos of replaced parts. The Jerry app helps customers get accurate quotes for their exact car from shops near them.

Check hybrid/EV requirements.

Many electric compressors require special POE oil and an isolation resistance test; using more common PAG oil can short the compressor.

DIY vs. Pro: Can I do this myself?

Whether you’re thinking about tackling your A/C compressor repair yourself or handing it off to a mechanic, Jerry can give you clear pricing on parts and shop labor. Here’s what to keep in mind when deciding if this is a good DIY job for you.

Related repairs

Because the compressor sits at the center of the A/C loop, nearby components often need replacement too. Jerry can help customers get quotes for multiple services near them. Here are some related repairs:

- Accumulator/drier

- Expansion valve or orifice tube

- Condenser (if contaminated or leaking)

- High/low pressure sensors, relays, modules

- Accessory belt and tensioner

- O-rings and seals

What our customers are asking

-

How long does an A/C compressor last?

-

Can I drive with a bad compressor?

-

Do I have to replace the drier and expansion device?

-

Will a recharge fix my A/C?

-

Why is R-1234yf so expensive?

-

How do I protect a new compressor?

-

What if only the clutch failed?

-

Is there a seasonal price difference?

Beginning with Hot Wheels toys as a preschooler, Rocco’s lifelong passion for cars has taken him from high school occupational courses to decades of master mechanic experience in mobile, dealership and independent auto shops.

Rocco’s professional career began in 1997 with factory Ford training in San Diego. While gaining invaluable experience in dealerships and independent shops, he went forward to complete Toyota factory training and graduated from the Universal Technical Institute near Chicago in 2009.

In 2014, Rocco opened Rocco’s Mobile Auto Repair in California servicing Los Angeles, Orange and San Diego Counties with both individual and fleet-based services. After years of success, Rocco shifted his work model from running a business to managing an independent automotive shop. Now in Tennessee, he focuses on training new technicians to be their best.

Steve Kaleff began working on cars at the very young age of nine years old, when his dad actually let him make fixes on the family car. Fast forward to the beginning of a professional career working at independent repair shops and then transitioning to new car dealerships. His experience was with Mercedes-Benz, where Steve was a technician for ten years, four of those years solving problems that no one could or wanted to fix. He moved up to shop foreman and then service manager for 15 years. There have been tremendous changes in automotive technology since Steve started his professional career, so here’s looking forward to an electric future!

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.