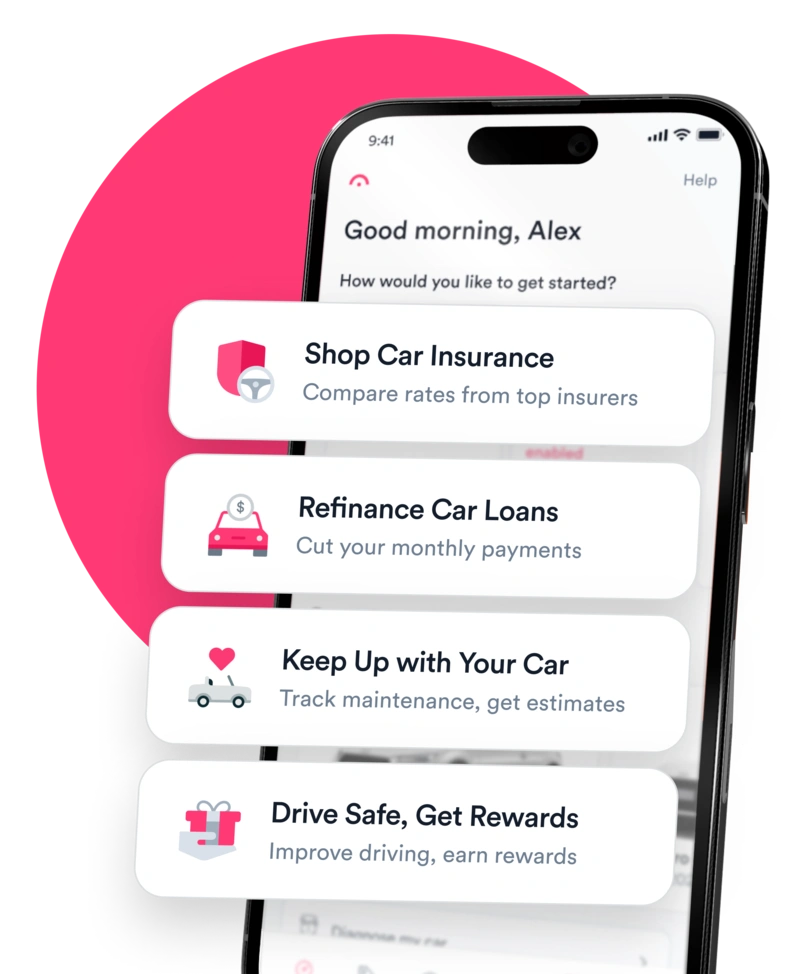

Exact prices will depend on your car and location. Use the Jerry app to price out these aspects of the repair and join other Jerry customers who improved their shop experience.

Real customers Jerry helped

The price range for an A/C recharge can vary based on your specific car, location, and parts used. But Jerry makes it easy to see what others are paying right now. Here are some examples of customers we’ve helped find the very best prices for their A/C recharges.

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

Cost breakdown: Why the price varies

Every day, Jerry helps drivers find fair prices for car repairs and has identified the most common reasons those prices can change:

Refrigerant type:

R-134a is cheaper; R-1234yf adds $100–$250 to the same service because of its higher material cost. These chemicals and air conditioning systems are not interchangeable. Substituting one for the other will cause damage to the A/C system and a very expensive repair.

Vehicle make/model and system capacity:

Larger systems or rear A/C/dual-zone setups need more refrigerant, often adding $25–$150 in materials.

Service fittings and small parts:

Schrader valves or service ports may need replacement ($20–$80 in parts plus labor).

Region and shop equipment:

High-cost metro areas and dealerships often charge $50–$150 more, especially for R-1234yf machines.

Pro tip: Refrigerant type and capacity drive most of the price, while labor and small parts make up the rest.

What is an A/C recharge?

An A/C recharge restores refrigerant and oil to your car’s air-conditioning system. Over time, leaks or service events can lower refrigerant levels, reducing cooling performance and lubrication. The professional process usually includes:

- Recovering and measuring the remaining refrigerant.

- Pulling a deep vacuum to remove moisture and check for gross leaks.

- Adding UV dye if requested.

- Recharging to the exact factory spec with refrigerant and oil.

- Verifying vent temperatures, pressures, fan operation and compressor function.

For R-1234yf systems, specialized machines and refrigerant are required. Hybrids and EVs often use POE oil and require high-voltage safety steps.

What are signs that I need an A/C recharge?

Low refrigerant shows up in several common ways. Here’s what Jerry has found you should look out for, from helping real drivers diagnose their car issues. If you notice these, you might be due for a recharge—or leak repair:

- Warm air at idle, cooler at highway speeds.

- A/C takes longer than usual to cool.

- Compressor clutch rapidly cycles on and off.

- Hissing from the evaporator area after shutdown.

- Oily residue at fittings or condenser.

- Visible dye from prior recharges around service ports.

- Frost or sweating on part of the low-pressure line.

Remember, a recharge just restores refrigerant—it does not fix the leak. If cooling fades again quickly, the system needs repair.

Your action plan: How to save money

There are a few proven ways to avoid overspending on an A/C recharge:

Confirm you actually need a recharge:

Check the cabin air filter, confirm condenser fans run, rinse debris from the condenser and inspect fittings for leaks before authorizing service.

Ask for the numbers:

Get a printout of recovered/charged amounts, vacuum hold and charge accuracy. Very little recovered refrigerant usually means there’s a leak.

Avoid “stop leak” cans:

They can damage equipment and components.

Pick the right shop:

Choose an EPA Section 609–certified shop with R-1234yf capability if applicable. Ask about a 30-day cooling/leak recheck policy.

Bundle services:

If you’re due for other maintenance, combining visits can cut shop fees.

Maintain airflow:

Clean filters and functioning cooling fans improve system performance.

DIY vs. pro: Can I do this myself?

DIY A/C recharges are possible but come with safety, legal, and accuracy risks. Whether you are leaving it to a pro or doing the A/C recharge yourself, Jerry can help you go into it with confidence by giving you pricing transparency over parts and labor costs.

Related repairs

If a leak is confirmed, the recharge is often paired with one or more additional repairs. Here are common examples and their cost ranges:

- Service port/Schrader valve: $80–$200

- O-rings and seals (localized): $120–$300

- Hose assembly: $200–$600

- Condenser: $350–$900

- Receiver/drier or accumulator + orifice/expansion valve: $200–$500

- Evaporator core (dash removal): $1,200–$2,200+

- Compressor (with flush/components): $700–$2,000+

Fixing the root cause prevents repeat recharges and protects the compressor from oil starvation. Use the Jerry app to compare prices and enhance your shop experience.

What our customers are asking

-

How often should I need a recharge?

-

Why is R-1234yf so expensive?

-

Will a recharge fix my leak?

-

Why vacuum first?

-

My compressor won’t engage—should I recharge?

-

How long does a recharge take?

-

Can I just add a parts-store can?

-

Do hybrids/EVs or rear A/C cost more?

Beginning with Hot Wheels toys as a preschooler, Rocco’s lifelong passion for cars has taken him from high school occupational courses to decades of master mechanic experience in mobile, dealership and independent auto shops.

Rocco’s professional career began in 1997 with factory Ford training in San Diego. While gaining invaluable experience in dealerships and independent shops, he went forward to complete Toyota factory training and graduated from the Universal Technical Institute near Chicago in 2009.

In 2014, Rocco opened Rocco’s Mobile Auto Repair in California servicing Los Angeles, Orange and San Diego Counties with both individual and fleet-based services. After years of success, Rocco shifted his work model from running a business to managing an independent automotive shop. Now in Tennessee, he focuses on training new technicians to be their best.

Steve Kaleff began working on cars at the very young age of nine years old, when his dad actually let him make fixes on the family car. Fast forward to the beginning of a professional career working at independent repair shops and then transitioning to new car dealerships. His experience was with Mercedes-Benz, where Steve was a technician for ten years, four of those years solving problems that no one could or wanted to fix. He moved up to shop foreman and then service manager for 15 years. There have been tremendous changes in automotive technology since Steve started his professional career, so here’s looking forward to an electric future!

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.