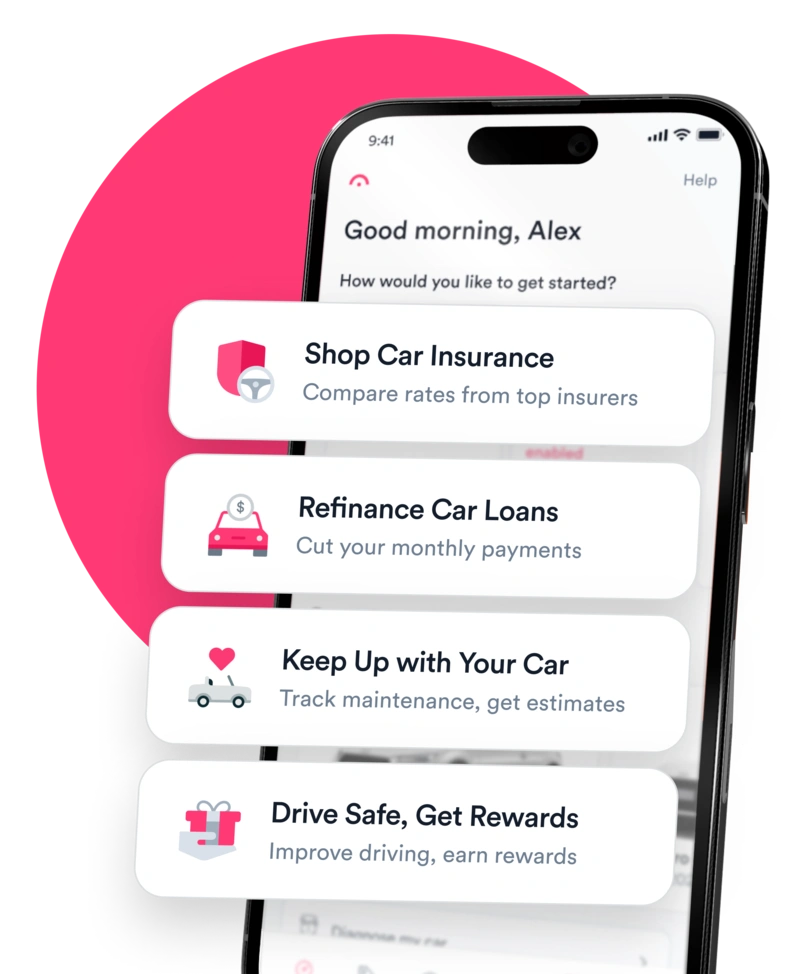

Exact prices will depend on your car and location. The Jerry app provides specialized diagnostic and pricing guidance to help customers dealing with repairs. Sign up for a better repair experience.

Real customers Jerry helped

The price you pay for an engine mount will depend on your car, where you live, and the parts installed. Jerry helps you quickly see what other drivers are spending today. Here are some examples of customers we’ve helped get the best prices available on their engine mounts.

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

Cost breakdown: Why the price varies

Each day, Jerry guides customers to competitive car repair prices, and has seen the same main reasons why those prices can change:

Number of mounts replaced:

One is cheapest; replacing two or more together saves overlap labor.

Mount type:

Rubber is cheapest, hydraulic costs more and active/electronic are the most expensive.

Vehicle layout and access:

Tight luxury bays, AWD crossmembers, and turbo plumbing raise labor time.

Part choice:

Aftermarket mounts can be 20–40% cheaper than OEM, but poor-quality units may cause vibration.

Labor rate/region:

Dealers and metro areas often charge 20–50% more than independents.

What is an engine mount?

An engine mount is a part that holds your car’s engine securely in place and connects it to the frame of the vehicle. Think of it as a heavy-duty bracket with a cushion built in. Most engine mounts have a rubber or fluid-filled center that sits between metal pieces. The metal provides strength to support the engine’s weight, while the rubber or fluid helps absorb vibrations so you don’t feel them as much inside the cabin.

Without good engine mounts, you’d feel a lot more shaking and banging when the engine is running or when you accelerate. Worn or damaged mounts can cause clunking noises, extra vibration in the steering wheel or seats, and sometimes a noticeable “jerk” when shifting from Park to Drive. You don’t normally see engine mounts unless a mechanic points them out, but they quietly do an important job: keeping your engine stable, secure, and as smooth and quiet as possible while you drive.

One customer’s car had severe vibration and noise inside the cabin. Inspection showed the engine mounts were crushed flat, so the engine was contacting the crossmember metal-to-metal. We replaced the mounts and the problem went away briefly, but the customer returned with the same symptoms. The replacement mounts had already failed.

The manufacturer then released a “revised” mount, which also failed in short order. Only after a second revision of the engine mounts did the repair finally hold. It was a good reminder that ongoing part defects can cause repeated failures, even when the repair is done correctly.

What are signs that you need engine mounts replaced?

Know the signs of a failing engine mount. Based on helping real drivers diagnose their cars, here’s what Jerry has learned you should watch for:

- Vibration at idle that improves at higher RPM.

- Clunk/thud on startup, shutdown, or when shifting.

- Noticeable engine lurch under throttle blips.

- New cabin buzzing/rattles.

- Visible cracks, separation, or hydraulic fluid leaks on the mount.

Your action plan: How to save money

Follow this action plan to clearly diagnose the issue and decide on next steps. It’s designed to help you and your mechanic get the repair done right the first time.

Confirm the diagnosis:

Misfires, bent wheels, or exhaust contact can mimic bad mounts. Check for hydraulic fluid leaks on oil filled mounts or large engine movement when engaging gears. Jerry customers use the app to help them diagnose their car issues with confidence before heading to the shop.

Get detailed quotes:

Ask for mount location, part brand/type, hardware, access notes, and alignment details. Request photos/videos of the torn mount.

Choose quality parts:

Sensitive vehicles do best with OEM or high-quality aftermarket.

Bundle wisely:

If several mounts show wear, replacing them together prevents repeat labor and higher costs. The Jerry app can provide quotes for multiple services at once.

Check for recalls/technical service bulletins:

Some active/vacuum-controlled mounts require relearn or software updates.

Time your visit smartly:

Mid-week appointments give shops more flexibility for rusted/seized bolts.

Pro tip: Symptoms that change with engine load (not road speed) usually point to mounts. Vibrations that track road speed usually mean tires or axles.

DIY vs. Pro: Can I do this myself?

No matter if you plan to tackle your engine mount at home or leave it to a shop, Jerry can provide transparent pricing for parts and labor. Here’s what to consider when deciding if this repair is right for DIY.

Pro tip: Always torque mounts at ride height to avoid preload that increases vibration. Many European cars use single-use bolts—replace them.

Related repairs

When an engine mount is on your to-do list, it’s worth checking if other connected repairs are needed too—combining them can save you money. Jerry helps you find solid, transparent pricing for several services at once.

- Transmission mounts and torque struts.

- Exhaust flex joints, hangers, and shields.

- CV axles and support bearings.

- Subframe and control arm bushings.

- Damper pulleys and accessory brackets.

- Radiator hoses and cooler lines (tension after engine shifts).

What our customers are asking

-

Can I drive with a bad engine mount?

-

Do I need all mounts replaced at once?

-

How long do mounts last?

-

Do mounts cause highway vibration?

-

Do I need an alignment after replacement?

-

How long does the repair take?

-

Can software fix vibration on active mounts?

-

Is it covered by warranty?

Beginning with Hot Wheels toys as a preschooler, Rocco’s lifelong passion for cars has taken him from high school occupational courses to decades of master mechanic experience in mobile, dealership and independent auto shops.

Rocco’s professional career began in 1997 with factory Ford training in San Diego. While gaining invaluable experience in dealerships and independent shops, he went forward to complete Toyota factory training and graduated from the Universal Technical Institute near Chicago in 2009.

In 2014, Rocco opened Rocco’s Mobile Auto Repair in California servicing Los Angeles, Orange and San Diego Counties with both individual and fleet-based services. After years of success, Rocco shifted his work model from running a business to managing an independent automotive shop. Now in Tennessee, he focuses on training new technicians to be their best.

Steve Kaleff began working on cars at the very young age of nine years old, when his dad actually let him make fixes on the family car. Fast forward to the beginning of a professional career working at independent repair shops and then transitioning to new car dealerships. His experience was with Mercedes-Benz, where Steve was a technician for ten years, four of those years solving problems that no one could or wanted to fix. He moved up to shop foreman and then service manager for 15 years. There have been tremendous changes in automotive technology since Steve started his professional career, so here’s looking forward to an electric future!

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.