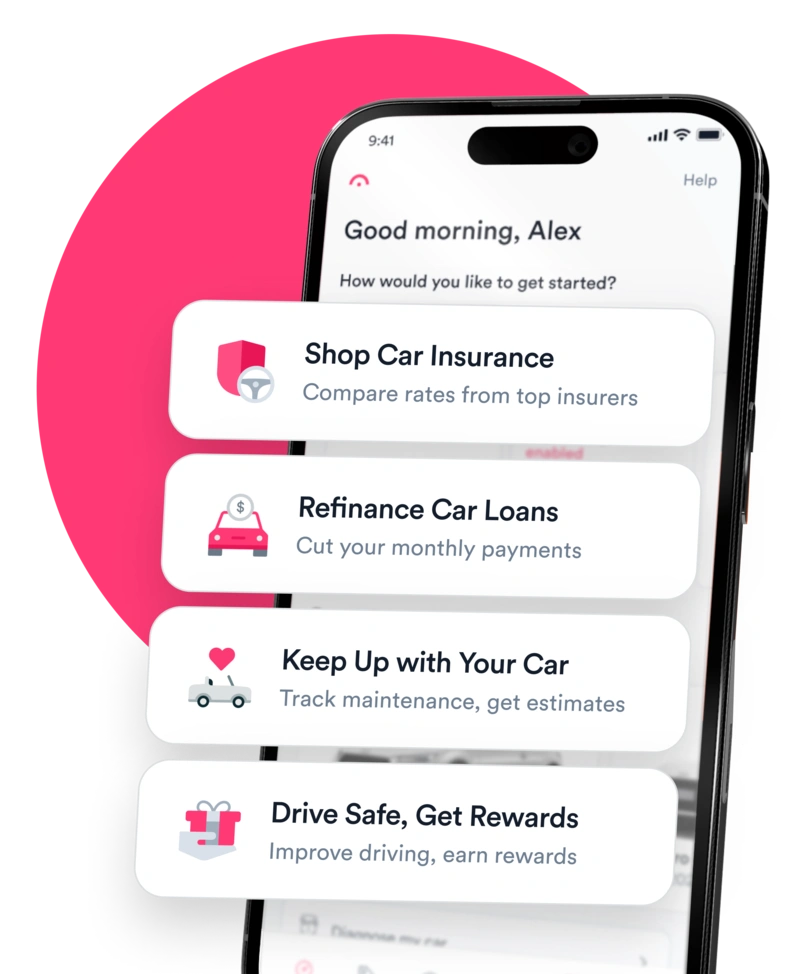

To get accurate quotes for your car and location, use a repair estimator like the one in the Jerry app.

Real customers Jerry helped

While pricing can vary based on location, parts used and exact vehicle, Jerry uses real customer experiences to show what drivers are paying right now. Here are some examples of customers Jerry has helped:

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

Cost breakdown: why the price varies so much

Your vehicle’s design drives the final bill. Here’s what Jerry customers are finding moves the needle (and how to read the clues like a pro):

Sensor type (bolt-in vs. integrated hub) — this is the biggest factor.

A bolt-in sensor is a separate part that bolts onto the wheel area, so it’s usually cheaper and quicker to replace, while an integrated hub assembly has the sensor built into the wheel bearing, meaning the whole hub gets replaced and costs more—often $250–$500 for the part alone.

Part type (active vs. passive):

Active sensors cost a bit more but support today’s driver-assist features.

Other potential parts:

The sensor might be fine. A cracked/corroded tone ring or a chafed wiring harness could be the real culprit.

Diagnostic time & labor rates:

Expect ~0.5 hr for scan/diagnosis (more if corrosion or intermittent faults exist). In high-rate metros and on rust-belt cars, totals trend higher.

The repair explained: what is a wheel speed sensor?

A wheel speed sensor tracks how fast each wheel is spinning and sends that info to your car’s ABS and stability/traction control systems. If it fails, you might see ABS/traction lights, lose those safety features, or notice odd brake pedal pulsing.

Replacement usually means inspecting the sensor and its wiring at the wheel hub, cleaning rust buildup, and swapping the sensor if it’s damaged or reading erratically. It’s often a straightforward job, but a corroded sensor or broken wire can add time.

Wheel speed sensors work like little magnets, so as your car ages they naturally collect tiny bits of metallic “gunk” (from normal brake and road wear). That buildup can mess with the signal and trigger ABS/traction control warnings. A smart first step is to clean the sensor area, clear the code, and see if it comes back.

Also pay attention to your tires. A brand-new tire is slightly taller than a worn tire because it has more tread. If you’ve got one new tire and the others are worn, that one wheel can spin at a slightly different rate—enough to look like a wheel speed sensor problem to the car’s computer. In that case, replacing the sensor won’t fix anything until the tire sizes match again.

Symptoms of a failing wheel speed sensor

A failed sensor can disable multiple safety systems at once, often lighting several dash icons together. Jerry customers are seeing these common symptoms:

- ABS, traction control, or stability control lights on.

- ABS or traction system kicking in unexpectedly at low speeds.

- Erratic speedometer on vehicles that use a wheel sensor for speed.

- Harsh or erratic transmission shifts on some platforms.

If your dash is lit up and you’re not sure where to start, download the Jerry app—our AI diagnostic can help interpret symptoms and point you toward next steps.

Your action plan: how to get it done right

Use this action plan to properly diagnose and resolve the issue. These steps will help you partner with your mechanic to make sure the repair is done correctly and efficiently.

Identify your sensor type:

Confirm bolt-in vs. hub-integrated by VIN or parts lookup. This will impact the overall labor time and cost.

Decide DIY or pro:

Balance comfort level against corrosion risk and tool needs. Hub jobs and seized sensors escalate quickly; incorrect axle-nut torque can shorten bearing life and trigger new ABS faults.

Get competing quotes:

Customers use the Jerry app to get real quotes from nearby shops.

DIY vs. pro: what to expect

Whether this is a DIY job depends on sensor type, climate (rust vs. sun-belt) and comfort level. Jerry can help you make a more informed decision with accurate parts and labor rates.

| Factor | DIY (Bolt-in Sensor) | Professional Service |

| Cost | $33 – $201 (part only) | $150 – $600+ |

| Time | 1–2 hours | 1–2 hours |

| Skill Level | Beginner–intermediate. Requires lifting the car safely | Professional |

| Risk | Low for bolt-in sensors; high for integrated hubs. | Low |

Related Repairs

If you’re replacing your wheel speed sensor, it can be smart to check on other related repairs at the same time—you may save money by bundling services. Jerry helps drivers find fair prices for multiple repairs in one visit.

- ABS tone ring/reluctor inspection: A cracked or rusty tone ring can mimic a bad sensor and keep triggering ABS lights.

- Wheel bearing/hub assembly check: Many sensors are integrated into the hub—bearing play or noise can point to a hub replacement instead.

- Brake inspection (pads/rotors): The wheel is already off, making it easy to spot uneven wear or heat damage.

- Brake fluid condition & ABS bleed: If the ABS module has been opened or there’s air in the system, an ABS-capable bleed may be needed.

- Harness/connector repair: Corroded connectors or damaged wiring near the wheel well are common causes of repeat sensor faults.

What our customers are asking

-

Can I drive with a bad wheel-speed sensor?

-

Will a bad sensor affect my inspection?

-

Do all four sensors fail at once?

-

What about used sensors?

Beginning with Hot Wheels toys as a preschooler, Rocco’s lifelong passion for cars has taken him from high school occupational courses to decades of master mechanic experience in mobile, dealership and independent auto shops.

Rocco’s professional career began in 1997 with factory Ford training in San Diego. While gaining invaluable experience in dealerships and independent shops, he went forward to complete Toyota factory training and graduated from the Universal Technical Institute near Chicago in 2009.

In 2014, Rocco opened Rocco’s Mobile Auto Repair in California servicing Los Angeles, Orange and San Diego Counties with both individual and fleet-based services. After years of success, Rocco shifted his work model from running a business to managing an independent automotive shop. Now in Tennessee, he focuses on training new technicians to be their best.

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.