On higher-end, AWD, and heavy-duty vehicles, expect $400–$800 per wheel, and complex jobs can reach $1,000+ if components are seized or sensors/hubs need replacement.

You can expect diagnostic time of $50–$150 if the shop needs to road-test and pinpoint the noise, which drives up the total cost to replace wheel bearings. If needed, an alignment adds $100–$200. Taxes, shop fees and ABS sensor add-ons bump up the price another $25–$150.

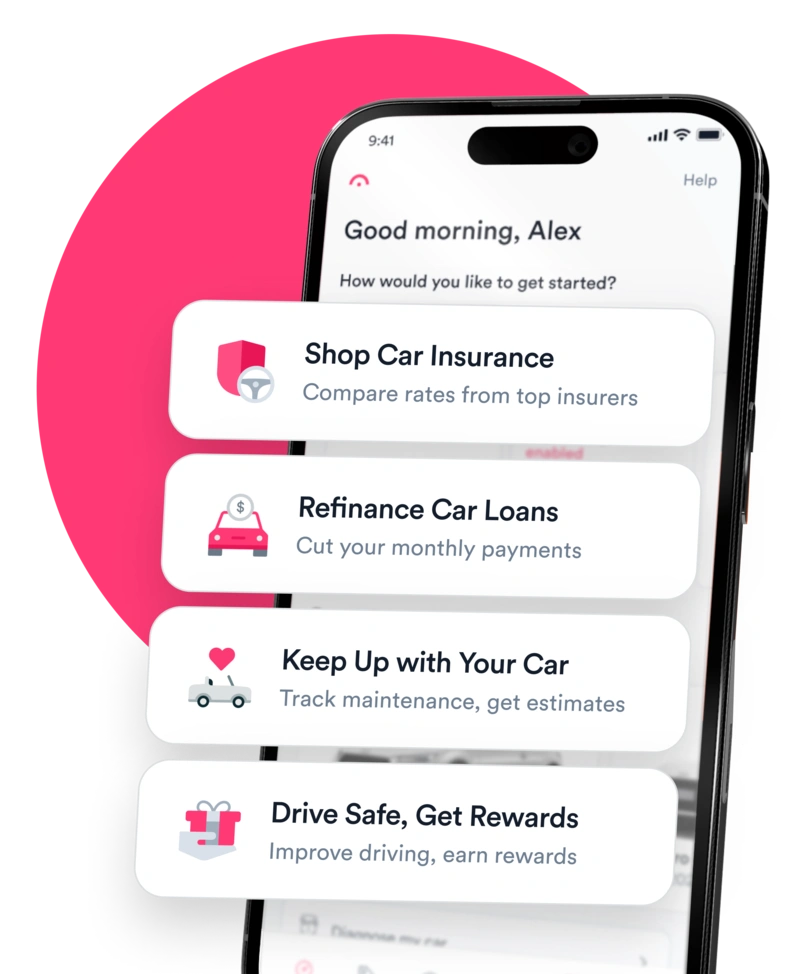

The Jerry app can help find accurate quotes for wheel bearing replacements for your exact car and location.

Real customers Jerry helped

The price range for a wheel bearing replacement can vary based on your specific car, location, and parts used. But Jerry makes it easy to see what others are paying right now. Here are some examples of customers we’ve helped find the very best prices for their wheel bearing repairs.

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

Cost breakdown: why the price varies

Jerry helps customers find good prices on car repairs, and found the most common reasons prices can vary:

Vehicle design (20–40% price difference):

Unitized hub assemblies are quicker than press-in bearings. Typical labor: hub 0.8–1.6 hr (cars), 1.5–2.5 hr (4×4); press-in 1.8–3.0 hr (more on Euro/AWD).

Part type and quality (15–30% price difference):

Premium hubs with integrated ABS sensors can cost 2–3x more than basic bearings. OEM/Timken/SKF/NTN usually run quieter and last longer.

Labor time and rust factor (20–50% price difference):

Rust-belt cars fight with seized bolts/corroded hubs. Common adders: stuck hub or axle (+0.5–1.0 hr), seized ABS sensor (+$40–$200), extraction time at shop rate.

ABS/speed sensor integration (5–15% price difference):

If the sensor fails or gets damaged, that’s an extra $40–$200.

Alignment needs (0–10% price difference):

Bolt-on hub only—usually no. Knuckle removal or loosened strut/camber bolts—yes ($100–$200).

One side vs. both (15–35% price difference):

Doing both saves a little overlap but doubles parts cost.

Shop rate and region (10–30% price difference):

Metro vs. rural and dealer vs. independent rates vary widely.

What is a wheel bearing?

A wheel bearing is the part that helps your wheel spin smoothly with as little friction as possible. It’s a precise set of steel balls or rollers that sits inside the wheel hub. On most modern cars it’s sealed, so when it wears out you replace the whole unit rather than servicing the bearing itself.

There are two common setups:

- A unitized hub assembly combines the bearing and hub into one bolt-on part, often with a built-in wheel-speed sensor for the ABS (anti-lock braking system).

- A press-in (cartridge) bearing is different. The bearing is pressed into the steering knuckle and the hub is pressed into the bearing. This style takes more labor and special equipment, which is why those jobs typically cost more.

When I was doing primarily suspension work, we’d regularly have clients bring their cars in with what turned out to be wheel bearing problems. The people who waited too long ended up having to replace the bearings, the wheel spindle and the brake rotor. The excess play from the damaged bearing took all those parts with it when it left. The clients that sought repairs in the early stages only needed bearings replaced–a major price difference.

Symptoms of failing wheel bearings

Know the signs of a failing wheel bearing. Here’s what Jerry has found you should look out for, from helping real drivers diagnose their car issues:

- Humming/growling that increases with speed: Classic bearing noise; often louder when loading that corner in a turn (e.g., louder turning left = right-side bearing likely).

- Rumbling/drone felt in the floor: Advanced wear transferring vibration into the chassis.

- ABS light or intermittent traction control: Many hubs have integrated sensors—bearing play can cause erratic readings.

- Wheel play at 12 and 6 o’clock: Any looseness suggests a failing bearing or ball joint; a tech can isolate which one.

- Uneven tire wear or heat near the hub: Prolonged drag affects tire wear and hub temperature.

- Red-line safety: Metallic grinding, obvious wobble, or hot-to-the-touch hub—stop driving and tow.

Your action plan: how to save money

To keep your costs down without sacrificing safety or longevity, follow this mechanic-approved game plan:

Confirm the symptom.

Speed-related hum/growl that changes when you steer is classic. Quick checks: rotate tires front-to-rear, do a gentle swerve test, scan wheel-speed PIDs for dropout, use an IR thermometer post-drive (a hotter hub can hint at drag).

Ask which design you have.

A bolt-on hub usually costs less in labor than a press-in bearing. Knowing this upfront helps you compare apples to apples.

Get multiple quotes with clear line items.

You want parts brand, labor hours, alignment, fees, and whether the hub includes an ABS sensor. Jerry customers use the app to get accurate repair quotes for multiple services at once.

Choose quality parts.

Cheap hubs get noisy fast. Prioritize OEM or reputable brands (Timken, SKF, NTN). Target a 24-month/24k-mile parts-and-labor warranty when possible.

Time it with related maintenance.

If brakes or struts are already off, piggybacking a bearing reduces overall labor.

Don’t delay.

Worn bearings accelerate tire and hub damage. If you feel wheel play, heat at the hub, metallic grinding, or wobble with ABS activation, park it and tow.

DIY vs. Pro: Can I do this myself?

DIY is realistic for bolt-on hubs if you have solid tools and rust-free hardware. Press-in bearings are advanced: you’ll need a hydraulic press or a high-quality hub/bearing service kit, plus precise torque specs. Whether you want to fix your ignition coil yourself or leave it to a pro, Jerry can help give you pricing transparency around parts and shop labor. Here is what to consider:

Related repairs

Wheel bearing jobs often overlap with other components. Jerry can help you get repair quotes for all of them to see how much you can save by bundling them together:

- ABS wheel speed sensor or harness: If integrated with the hub or damaged by corrosion.

- Hub assembly: Required when the bearing and hub are one unit.

- CV axle or axle nut: Worn splines or seized axle can necessitate replacement; many axle nuts are single-use—replace and torque to spec.

- Brakes (pads/rotors): If they’re worn and already off the car, parts cost may be the only extra.

- Knuckle/bearing seals and snap rings: Often replaced during press-in jobs.

- Alignment: Needed when camber bolts or strut-to-knuckle bolts are loosened.

Ready to compare real prices from local shops and get your car up to speed? Download the Jerry app for quick, transparent quotes on a wheel bearing replacement and any related repairs.

What our customers are asking

-

Is it safe to drive with a bad wheel bearing?

-

Should I replace bearings in pairs?

-

How long do wheel bearings last?

-

Do I need an alignment after a bearing?

-

Can tire noise mimic a bad bearing?

-

Why is the ABS light on with a bearing issue?

-

Can I just repack the bearing?

-

What if I ignore the noise?

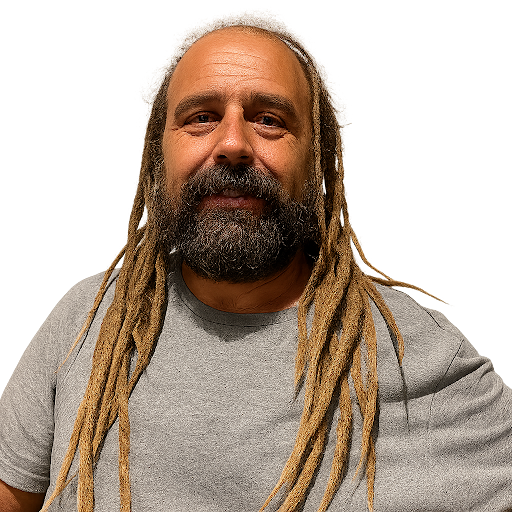

Beginning with Hot Wheels toys as a preschooler, Rocco’s lifelong passion for cars has taken him from high school occupational courses to decades of master mechanic experience in mobile, dealership and independent auto shops.

Rocco’s professional career began in 1997 with factory Ford training in San Diego. While gaining invaluable experience in dealerships and independent shops, he went forward to complete Toyota factory training and graduated from the Universal Technical Institute near Chicago in 2009.

In 2014, Rocco opened Rocco’s Mobile Auto Repair in California servicing Los Angeles, Orange and San Diego Counties with both individual and fleet-based services. After years of success, Rocco shifted his work model from running a business to managing an independent automotive shop. Now in Tennessee, he focuses on training new technicians to be their best.

Steve Kaleff began working on cars at the very young age of nine years old, when his dad actually let him make fixes on the family car. Fast forward to the beginning of a professional career working at independent repair shops and then transitioning to new car dealerships. His experience was with Mercedes-Benz, where Steve was a technician for ten years, four of those years solving problems that no one could or wanted to fix. He moved up to shop foreman and then service manager for 15 years. There have been tremendous changes in automotive technology since Steve started his professional career, so here’s looking forward to an electric future!

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.