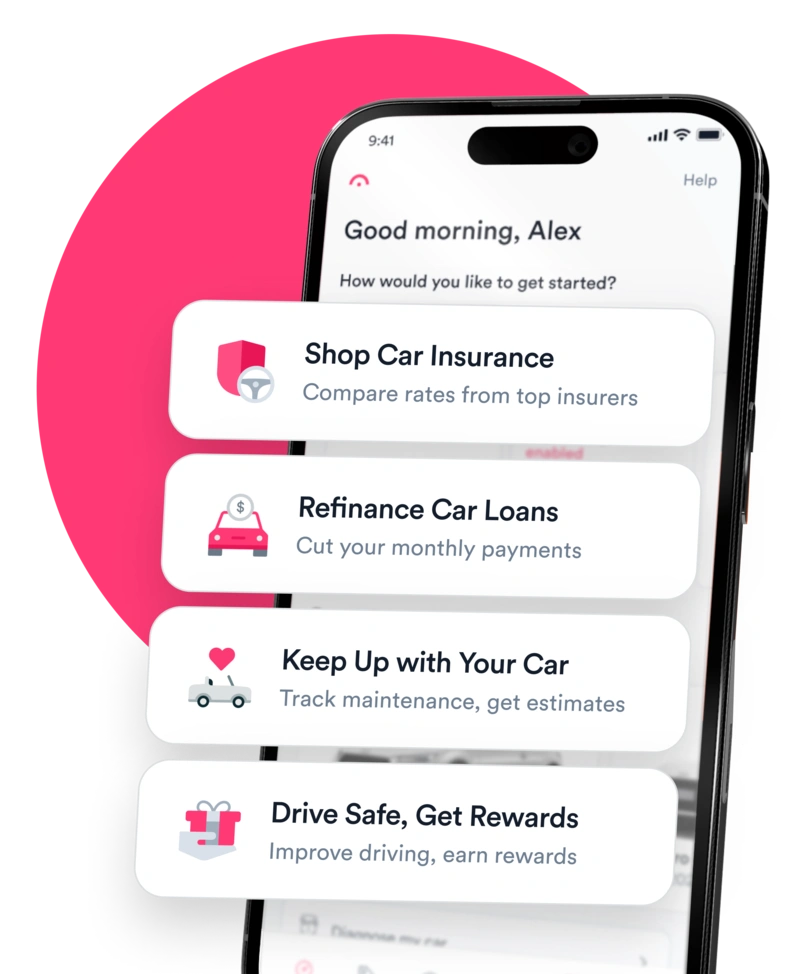

Your exact price will depend on your car and location. You can use the Jerry app to see local prices on the engine air filter and other components. Join other customers who’ve taken some of the hassle and uncertainty out of the repair process.

Real customers Jerry helped

The cost of an engine air filter replacement depends on your specific vehicle, where you live, and the parts you choose. With Jerry, you can quickly see what other drivers are paying right now. Below are a few real examples of customers we’ve helped secure the best available prices on their engine air filter replacements:

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

Cost breakdown: Why the price varies

Jerry helps customers track down great repair prices every day, and learned there are a few key reasons those prices can differ:

Filter type and quality:

Basic paper filters run $10–$25 while premium OEM or high-flow versions add $10–$60. Note that reusable/oiled filters cost $50–$100 upfront.

Vehicle design and access:

Easy-access boxes take 10 minutes, but if the filter is buried under other parts or has a dual setup dual setups, you can expect another 0.2–0.5 labor hours. Some Euro/turbo models even need 0.7–1.0 hours.

Shop type and labor rate:

A 0.3-hour job may cost $30 at an independent but $60+ at a dealer.

Region and market:

Urban/coastal areas often add $10–$40 compared to rural areas.

What is an engine air filter?

An engine air filter is a simple but important part under your hood that helps your car “breathe.” Your engine needs clean air to mix with fuel and create the power that moves your car. The air filter’s job is to catch dust, dirt, leaves, and other debris before they get into the engine. Without it, all these contaminants could scratch and wear out internal parts, reduce performance, and shorten the life of the engine.

Over time, the filter gets dirty and clogged, just like the filter in your home’s HVAC system. Replacing an engine air filter is usually quick and inexpensive, and many drivers are surprised by how simple it is. Keeping it fresh is an easy way to help your car run smoothly and efficiently with very little effort on your part.

Over the years, I’ve seen a few cars where the air filter alone was causing real problems. One engine wouldn’t even start—just taking out the clogged air filter was enough to get it running again.

In another case, a car kept failing its smog test. We didn’t adjust anything complicated: we just changed the engine oil and swapped in a new air filter. On the very next test, it passed.

Air filters are inexpensive and usually simple to change. If you replace yours at the intervals your owner’s manual recommends, you’ll avoid a lot of headaches and help your engine run cleaner and smoother with almost no effort.

What are signs that you need the engine air filter replaced?

Know the signs of an engine air filter in need of replacement. Based on helping real drivers diagnose their cars, here’s what Jerry has learned you should watch for:

- Heavily clogged or dirty pleats.

- Sluggish acceleration or weak throttle response.

- Reduced fuel economy.

- Louder intake noise or whistling from a loose airbox.

- Check Engine Light or airflow codes (P0101, P0171).

- Oil or debris inside the airbox.

- Performance drop after dusty trips.

Your action plan: How to save money

These steps will help you partner with your mechanic to make sure the repair is done correctly and efficiently:

Inspect visually:

Some gray is fine; replace when light doesn’t pass through or pleats are clogged/torn.

Bundle with other services:

Have it swapped during an oil change or brake check to save on labor. Jerry customers use the app to get quotes for multiple services at once.

DIY if accessible:

Most airboxes use clips or screws—easy for a careful driver.

Protect the MAF:

Seat the lid evenly, avoid leaving the box open, and use proper oiling technique for reusable filters.

Ask for proof:

Request to see your old filter and confirmation all clips/latches are sealed.

Jerry recommends: Quality paper filters from Mahle, Mann, Denso, or ACDelco are best for daily drivers.

DIY vs. Pro: Can I do this myself?

No matter if you plan to tackle your engine air filter replacement at home or leave it to a shop, Jerry can provide transparent pricing for parts and labor. Here’s what to consider when deciding if this repair is right for DIY

Related repairs

When you need a new engine air filter, you might want to look into other related services too—bundling them can lower your overall cost. Jerry makes it easy to compare reliable prices for several repairs at once.

- Cabin air filter: $78–$106 installed.

- MAF sensor cleaning/replacement: $70–$150 cleaning; $150–$400+ for replacement.

- Intake boot/duct: $75–$200 installed if cracked.

- Clips/lid/snorkel hardware: $5–$20 each.

- Throttle body cleaning: $100–$180 if the plate sticks.

Use the Jerry app to get repair estimates in advance so you’re not caught off guard if the technician recommends further services.

What our customers are asking

-

How often should I replace the filter?

-

Can a dirty filter damage the engine?

-

Do performance filters help?

-

Can I clean a paper filter?

-

Why did my shop charge $100+?

Beginning with Hot Wheels toys as a preschooler, Rocco’s lifelong passion for cars has taken him from high school occupational courses to decades of master mechanic experience in mobile, dealership and independent auto shops.

Rocco’s professional career began in 1997 with factory Ford training in San Diego. While gaining invaluable experience in dealerships and independent shops, he went forward to complete Toyota factory training and graduated from the Universal Technical Institute near Chicago in 2009.

In 2014, Rocco opened Rocco’s Mobile Auto Repair in California servicing Los Angeles, Orange and San Diego Counties with both individual and fleet-based services. After years of success, Rocco shifted his work model from running a business to managing an independent automotive shop. Now in Tennessee, he focuses on training new technicians to be their best.

Steve Kaleff began working on cars at the very young age of nine years old, when his dad actually let him make fixes on the family car. Fast forward to the beginning of a professional career working at independent repair shops and then transitioning to new car dealerships. His experience was with Mercedes-Benz, where Steve was a technician for ten years, four of those years solving problems that no one could or wanted to fix. He moved up to shop foreman and then service manager for 15 years. There have been tremendous changes in automotive technology since Steve started his professional career, so here’s looking forward to an electric future!

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.