Note: Many GDI (gasoline direct injection) vehicles have two pumps—an in-tank low-pressure pump and an engine-mounted high-pressure pump (HPFP). The prices here refer to the in-tank pump; the HPFP cost is separate.

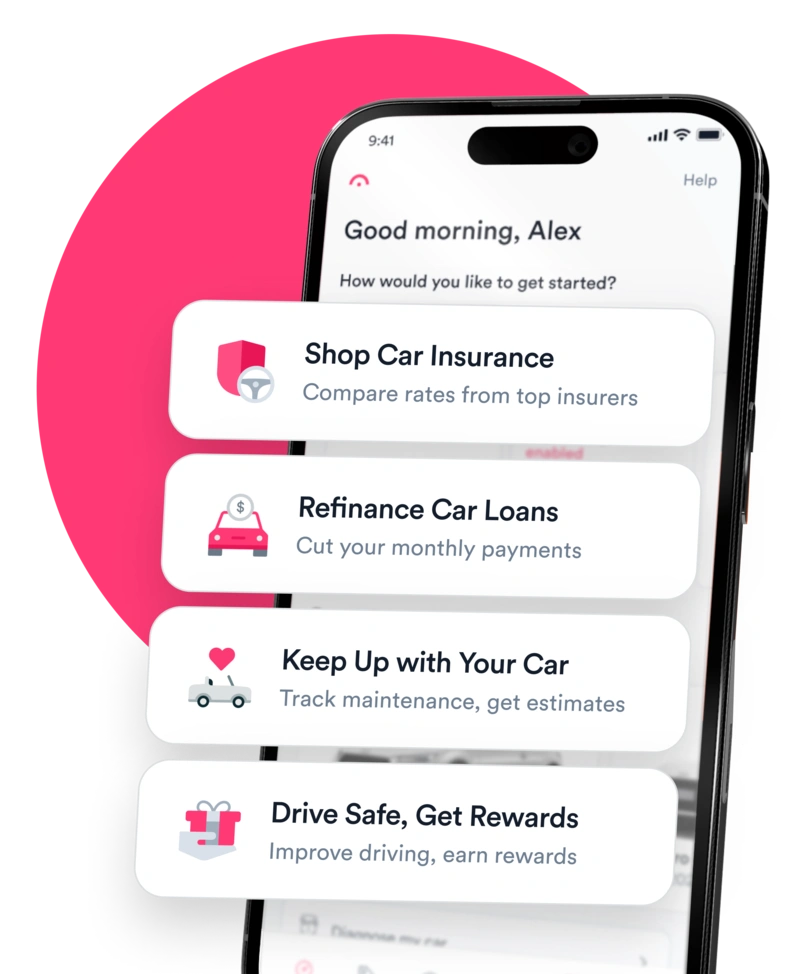

Download the Jerry app to instantly compare local shop quotes and stay ahead of any repair surprises.

Real customers Jerry helped

While pricing can vary based on unique factors, Jerry uses real customer experiences to show what drivers are paying right now. Here are some customer examples:

Estimates are modeled based on real vehicle and location data; names have been changed. Actual prices will vary by shop, parts, and vehicle condition.

What is a fuel pump?

Your fuel pump delivers gasoline from the tank to the engine at precise pressure and volume. In modern fuel-injected vehicles, this is an electric in-tank pump (often packaged with a strainer and level sender).

- Older carbureted engines: Mechanical pumps on the engine (rare today).

- Modern FI vehicles: In-tank electric pump module.

- GDI systems: Add a high-pressure pump on the engine, fed by the in-tank pump.

- Some Euro/modern SUVs: May also use transfer or auxiliary pumps.

Think of it as the heart of your fuel system: steady pressure = smooth starts, crisp throttle response and power under load.

Signs you need a fuel pump replaced

Jerry customers are seeing these classic fuel pump symptoms:

- Long cranking or no-start (especially after sitting overnight).

- Stalling or stumbling at highway speeds or uphill.

- Loss of power, surging or hesitation that improves when easing off throttle.

- High-pitched whining from the tank.

- Low fuel pressure on gauge—or pressure that drops under load.

- Erratic fuel gauge (level sender failure).

- Pump quits when hot, works when cool — a classic “dying pump” sign.

Pro tip: Most modern vehicles use a fuel pump that is replaced as a unit, containing the pump, strainer/filter, sending unit and fuel pump level float. That makes it much more expensive to replace.

Cost breakdown: Why the price varies

Fuel pump pricing isn’t just about the pump itself. Jerry customers are seeing a few factors that can swing totals by hundreds:

Vehicle design & access:

Access panel under the seat = 1.5 hr labor. Tank drop = 3–4 hrs. That’s $200–$400 more in labor.

Pump type (module vs. pump-only):

Modules (pump + strainer + level sender) cost more but restore everything. Pump-only can save $100–$300 but may leave other worn parts in place.

OEM vs. aftermarket:

Original equipment manufacturer (OEM) is pricier but quieter and longer-lived. Quality aftermarket (Delphi, Denso, Bosch, Carter, Pierburg) saves 15–40%. Avoid ultra-cheap pumps with high failure rates.

Labor rate & location:

Shop rates vary $90–$180+/hr. Metro areas trend higher by $150–$300 per job.

Diagnosis & contamination:

Confirming a weak pump (vs. electrical or HPFP fault) adds $50–$150. Tank cleaning/line flush for rust or debris adds $100–$300.

Fuel level & safety:

Working with a full tank is heavier and riskier, adding up to 0.5 hr in additional labor.

Rust Belt realities:

Corroded straps, studs or lock rings add parts and labor. Expect new seals, possibly tank straps.

System nuances (GDI/Euro):

Some vehicles have multiple pumps (low-side, high-side, transfer/auxiliary).

Shop policies:

Parts markup of 25–50% is common. Some apply diagnostic fees toward the repair. Always check for recalls, Technical Service Bulletins (TSB) or extended warranty coverage.

Your action plan: How to save money

Keep costs under control with this approach:

Confirm the diagnosis:

Ask for KOEO (key on, engine off) and running pressure tests, volume test, and voltage/ground checks. Inspect relays, wiring, pump ground, and control modules (Ford FPDM, Chrysler TIPM). On GDI, verify both low- and high-side pressures. The Jerry app’s diagnostic tool can help sort through your symptoms as well.

Compare parts options wisely:

Request reputable brands with solid warranties (12/12 or better). Always replace the strainer and serviceable filter with the pump.

Reduce labor time where possible:

If an access panel exists, (don’t cut one). Budget for seals/lock rings.

Prevent repeat failures:

If contamination is found, approve tank cleaning and line flush. A new pump will fail early in a dirty system.

Plan fuel level/timing:

Show up with <1/4 tank to save time and labor.

Get apples-to-apples quotes:

Specify part brand, replacement of strainer/seals, tank cleaning if needed, and warranty terms. Ask how the shop will verify the repair (pressure under load, leak test, level sender calibration).

DIY vs. Pro: Can I do this myself?

DIY pump replacement is possible for skilled DIYers—but it’s messy, risky and hardware-intensive. Jerry offers customers insight into parts and labor pricings, to help make the right decision:

DIY safety notes: Disconnect battery, ventilate, keep extinguishers nearby. Relieve pressure, support the tank, replace the seal/lock ring, lube the O-ring, torque properly and verify pressure/leaks. Calibrate the level sender if required.

Do your research and find out where the fuel pump is in your car. If it’s in the tank, keep the information in the above paragraph in mind. If your car has a fuel pump outside the tank or if there’s an access panel that allows you to replace the fuel pump without removing the fuel tank, your job is much easier.

Related repairs

Fuel pumps rarely fail alone. Jerry customers are often bundling them with:

- Fuel filter/strainer (if serviceable): Always replace with the pump.

- Relay, fuse, wiring pigtail, inertia switch (Ford), FPDM (Ford/Lincoln), TIPM (Chrysler/Jeep): Electrical issues can mimic pump failure.

- Fuel pressure regulator/control module or FRP sensor: Can cause similar codes.

- Fuel level sending unit: Integrated into many pump modules. Replace if glitchy.

- Tank cleaning & line flush: Essential if rust, debris or bad fuel is found.

- Tank straps, lock ring, seals: Replace if corroded.

- On GDI: High-pressure fuel pump if rail pressure issues persist.

What our customers are asking

-

How long does a fuel pump last?

-

Can I drive with a failing pump?

-

Do I need to replace the filter/strainer with the pump?

-

How do I know it’s not wiring or relays?

-

Do fuel pumps need programming?

-

What’s a realistic budget?

-

How can I extend pump life?

Spencer Clayton is a mechanic, writer and fabricator who has hands that know their way around engines and a passion for storytelling. He’s diagnosed complex faults, built high performance engines and custom fabricated everything from fine detail parts to entire chassis while sharing how things work and why they matter. His background in everything from dealership technician work to building high performance cars spans a large breadth of experience, and he is driven by a love of all things automotive and a desire to share knowledge.

Steve Kaleff began working on cars at the very young age of nine years old, when his dad actually let him make fixes on the family car. Fast forward to the beginning of a professional career working at independent repair shops and then transitioning to new car dealerships. His experience was with Mercedes-Benz, where Steve was a technician for ten years, four of those years solving problems that no one could or wanted to fix. He moved up to shop foreman and then service manager for 15 years. There have been tremendous changes in automotive technology since Steve started his professional career, so here’s looking forward to an electric future!

Nick Wilson is an editor, writer, and instructor across various subjects. His past experience includes writing and editorial projects in technical, popular, and academic settings, and he has taught humanities courses to countless students in the college classroom. In his free time, he pursues academic research, works on his own writing projects, and enjoys the ordered chaos of life with his wife and kids.